our

products

We believe that the climate crisis requires sustainable solutions at scale. So, we target ingredients and materials across some of the largest industries that have some of the most harmful, polluting or complex supply chains to show that you can instead have responsibly sourced, transparent, and traceable products — made from the sustainable source™. Geno focuses our technology to only design sustainable materials that at scale can have a real (and really big) impact.

Our technology powers many of the materials used in the products you use, wear or eat every day. We strongly believe that the process of making every material can be redesigned to be better for our planet.

We believe that the climate crisis requires sustainable solutions at scale. So, we target ingredients and materials across some of the largest industries that have some of the most harmful, polluting or complex supply chains to show that you can instead have responsibly sourced, transparent, and traceable products — made from the sustainable source™. Geno focuses our technology to only design sustainable materials that at scale can have a real (and really big) impact.

Our technology powers many of the materials used in the products you use, wear or eat every day. We strongly believe that the process of making every material can be redesigned to be better for our planet.

innovation

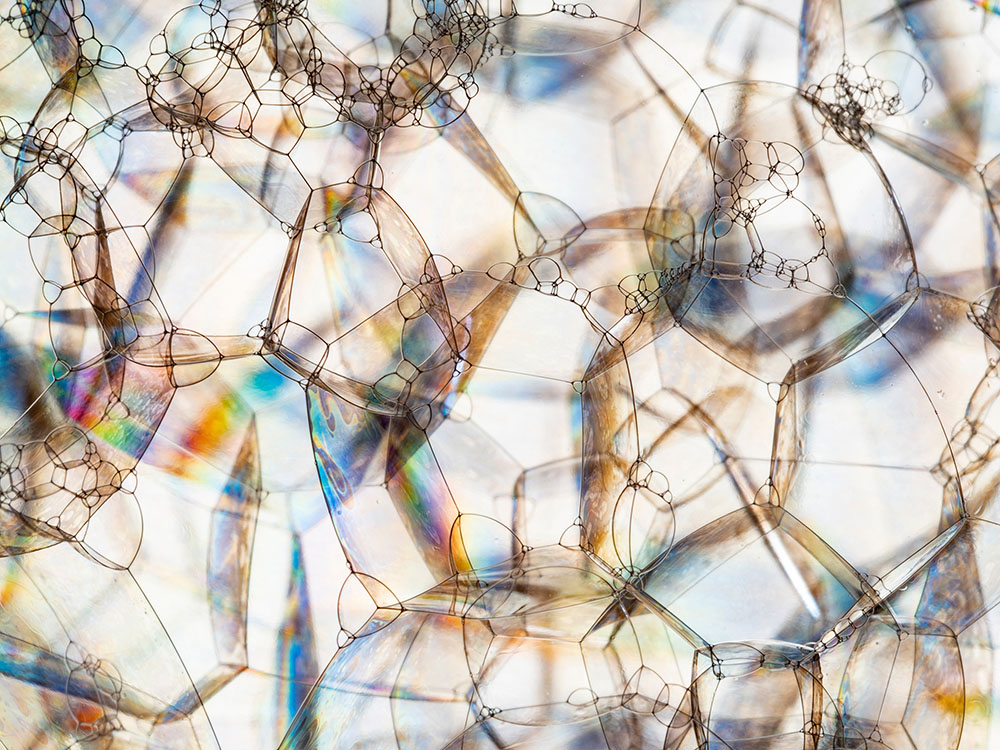

Innovation can often be the driver of industrial transformations and that is the case for the materials transition. Our technology and capabilities, developed and honed over two decades, harness the ever-increasing power of biotechnology, where microorganisms and industrial processes are designed to ferment plant sugars into materials and ingredients. Geno Innovation Center is home to our world-class research and development team of engineers and scientists who have deployed more than $300 million in technology investment, collaborating to create a portfolio of 1,800 patents and applications. The IP covers product pathways, synthetic biology approaches to engineering microorganisms, processes to bio-manufacture products, their sometimes-unique biological compositions and product applications. We work closely with some of the world’s leading brands to develop solutions that align superior performance and economics with sustainability. We produce and market our own branded products. In addition, we license our Geno technology to some of the world's largest manufacturers including Novamont and Qore® (a joint venture of Cargill and HELM).

Geno technology powers

Geno's nylon

learn more >Geno’s plant-based nylon is transforming the industries that have relied on fossil fuel-based nylon, leading the $22 billion market’s transition to more sustainable materials.

We were lululemon’s first-ever equity investment in a sustainable materials company, and we’re helping them transition the nylon in their products (made from fossil fuels) to our plant-based nylon.

Brontide® butylene glycol is our multifunctional ingredient for personal care products that deliver high performance and sustainability. It can be used to enhance the texture of moisturizers or improve antimicrobial efficacy.

Most butylene glycol products on the market today are sourced from fossil fuels and are made from acetaldehyde, a carcinogen. Our sustainable process reduces the global warming potential by more than an estimated 50% compared to the petroleum-based butylene glycol production process. We’re lucky to work with some of the world’s largest beauty brands as they transition their butylene glycol (it’s found in many of the products in your skincare routine) to Brontide®.

Avela™ natural (R)-1,3 Butanediol is a ketogenic ingredient, offering an easy and accessible way to raise ẞ-hydroxybutyrate (BHB) levels.

Made from plant sugars using Geno’s proprietary fermentation process, Avela™ provides a kick-start to the benefits of ketosis: more endurance, more clarity, more energy.

Geno™ Bio-BDO

learn more >Renewable bio-BDO (bio-1,4-butanediol), produced by Geno™ Bio-BDO process technology from plant sugars instead of fossil feedstocks, is a major chemical intermediate that replaces conventional fossil-based BDO for direct use in a diverse range of everyday materials and consumer products, from spandex to shoes to plastics in cars and electronics.

The fully proven and transformative Geno™ Bio-BDO process technology offers significant carbon avoidance potential and competitive economics compared to conventional BDO in the market. Over 2.5 million tons of 1,4-BDO are produced annually worldwide. If all the BDO was produced using Geno’s technology, over 14 million tons of greenhouse gases per year would be eliminated, the equivalent of taking 3 million cars off the road.

Geno fragrances

Our Geno performance bio-specialties are the more sustainable and scalable building blocks of fragrances that are often both difficult to source responsibly from nature and expensive.

Geno products can enable high-performing fragrances with cost savings, improved customer safety and sustainability impacts.

ideation lab

contact >Our Geno technology continues to drive more sustainable materials, ingredients and brands. Our core business model prioritizes developing well-known and established large-scale commodities and specialty ingredients because we want to drive the greatest impact possible. If you are a brand or inventor passionate about scaling material solutions or addressing an unsustainable source for existing ingredients, contact our team to see if Geno technologies could help you design, develop and scale more sustainable solutions.